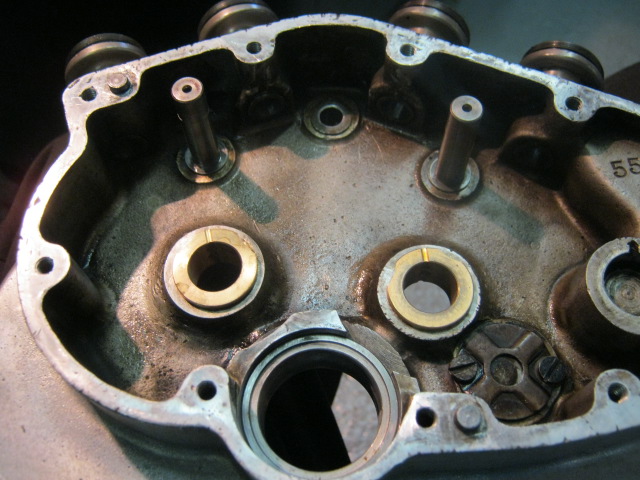

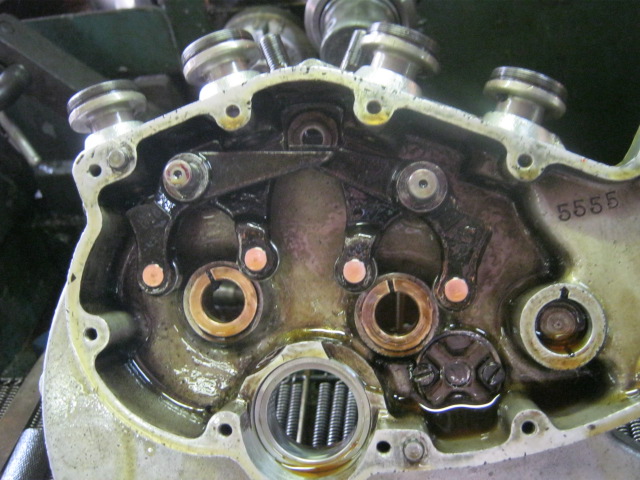

Here are some pictures of the gear train and valve system of the motor. New bushings where needed. There were a few that had failed. The new shinny rollers look soooo nice.

- Comment

- Reblog

-

Subscribe

Subscribed

Already have a WordPress.com account? Log in now.

You have a serious problem here that in fact can seize up the engine. The wrong crankcase ventilation valve body is mounted and that needs to be addressed before the first start of the engine! What you got mounted there is the earlier valve body where the function is REVERSED compared to the valve body that should be on the engine. That valve opens up when there is a overpressure in the crankcase and closes when there is a underpressure. The reversed function will result that too little oil is sucked into the crankcase and starve the cylinders and rod bearings from enough oil. You have on your engine done a very common modification of the crankcase ventilation system and moved the ventilation tube from the left hand side crankcase to the cam cover on the right hand side effectively changed the direction the air is ventilated out from the engine. With this modification it is imperative to remove the valve body entirely and drill up the 5 existing small holes to one big hole to at the minimum 8mm or 5/16 inch and preferable to 9,5mm or 3/8 inch. That one big hole will allow enough air and oil mist to be transported in and out of the crankcase with the pulsating air flow that is produced by the pistons movement. The existing 5 tiny holes in the crankcase are restrictive and will result in too high crankcase pressure when the engine is running. The small holes are restrictive for a purpose with the original direction of air transport, but that does not work well when the direction is changed. With too high crankcase pressure, not enough oil will be transferred from the cam compartment into the crankcase. The 1928-29 Indian crankcase ventilation holes and valves work in conjunction, you have small restrictive holes on the right hand crankcase and a larger, less restrictive valve and hole on the left hand side. When there is a overpressure, the cam side valve closes and the left valve opens with its less restrictive hole and air is escaping. When the pistons travels up that results in a slight underpressure in the crankcase that sucks oil through the holes, but also through the pinion shaft. With the 1930-31 ventilation system when the air transportation is reversed like your modification. But the pinion oiling system is slightly altered, the 1930-31 oil pump is different than yours, it is pumping oil to the center of the pinion shaft (very marginally and ineffective in my opinion). However the cylinder and rod lubrication still rely almost entirely on the oil mist that is transported through and fro the valve ventilation hole. That is why the pressure difference between the cam compartment and the crankcase must be small and the hole must be large, a overpressure in the crankcase is preventing oil entering the crankcase. Especially with the 1928-30 oil pump that you have.

LikeLike