You are going to see a pretty big jump in the project. When I get in the swing of working I oftern forget to take pictures. Well that is exactly what happened. Anyway, Here is the update. Lots of parts went on the bike.

Testing the headlight. I kept the electrical 6 volts even though I was not planning to run the generator. At least this way I can if I want to.

Dash and Horn install. This all came back off to run the wiring harness and control cables. Just for fun I wanted to keep one part of the bike unrestored. When looking at the Indian headers horn I knew this was the part. It just looked perfect the way it is so I left it alone. Its also very easily removable if I ever do decide to have it re-plated.

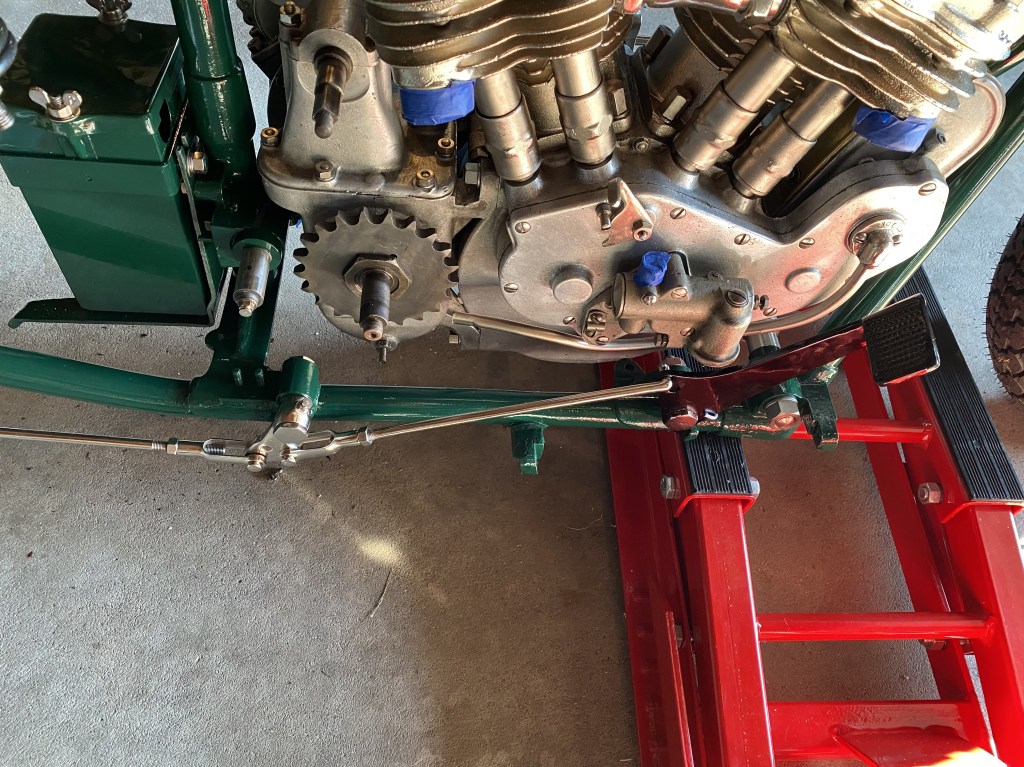

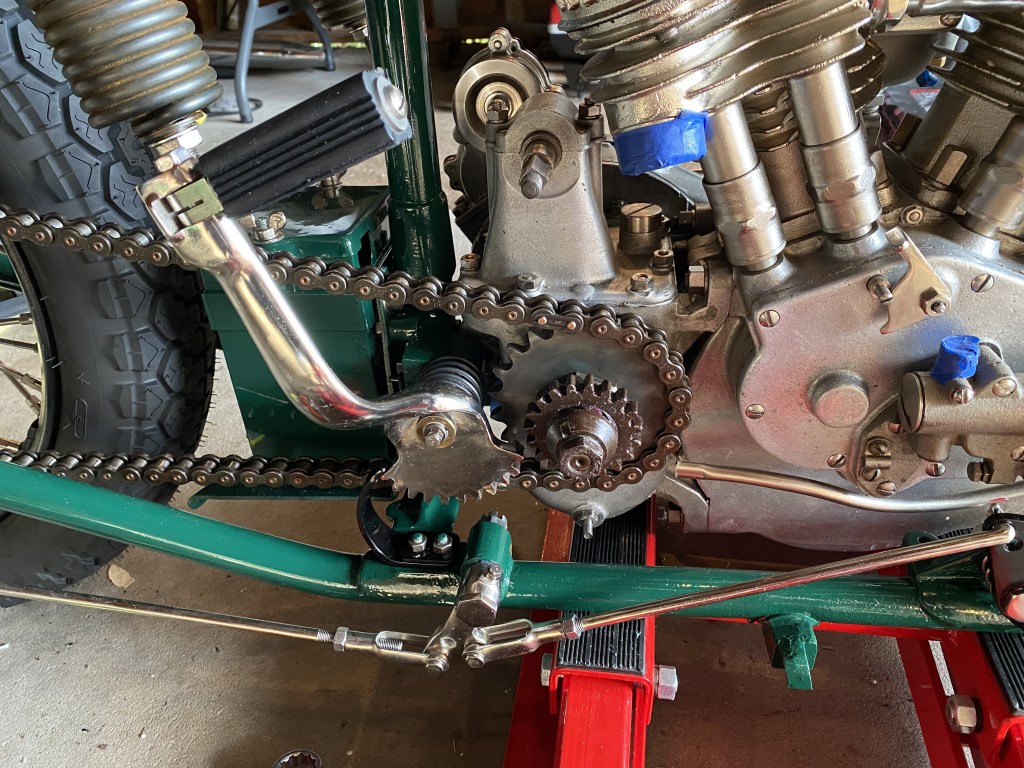

And here is where I forgot to document with pictures. Some of the things that were completed during this time. Front break control, Horn and horn button wiring, Headlight and wiring harness, exhaust header pipes and muffler, rear light and plate holder, throttle and spark advance controls, oil lines and gas line. I am sure I am missing a few things. Here is the only picture I can find of this time. You can see the horn button wire coming out of the handlebars. Threading that through was not and easy task. Also getting the oil handpump operating was also a bit tricky. Dug into the shop manual to get a really good idea of what is going on. Cut a new piece of leather for the cup seal and now it works great. Having an operating hand pump makes filling the crank case soooo much easier. A full stroke of the pump puts allot of oil in the case. Very easy to overfill if not careful.