I had a few setbacks wile running the scout in. I learned through the 101 association that it is best practice to snug down the head bolts at 1 min, 1 mile, 5 miles and 20 miles. At that point the heads should be pretty much snugged into the gasket and are usually good to go with minimal fuss after that. Well for some reason two of the head bolts in the front cylinder seized up and they were giving me a false sense of snugness. They felt like they were tightened down because they were stuck. all the others snugged down the tiniest bit with each heat cycle and check. Wouldn’t you know it one of the first longer rides I start hearing a strange sound that turned out to be gasses leaking out due to a blown head gasket.

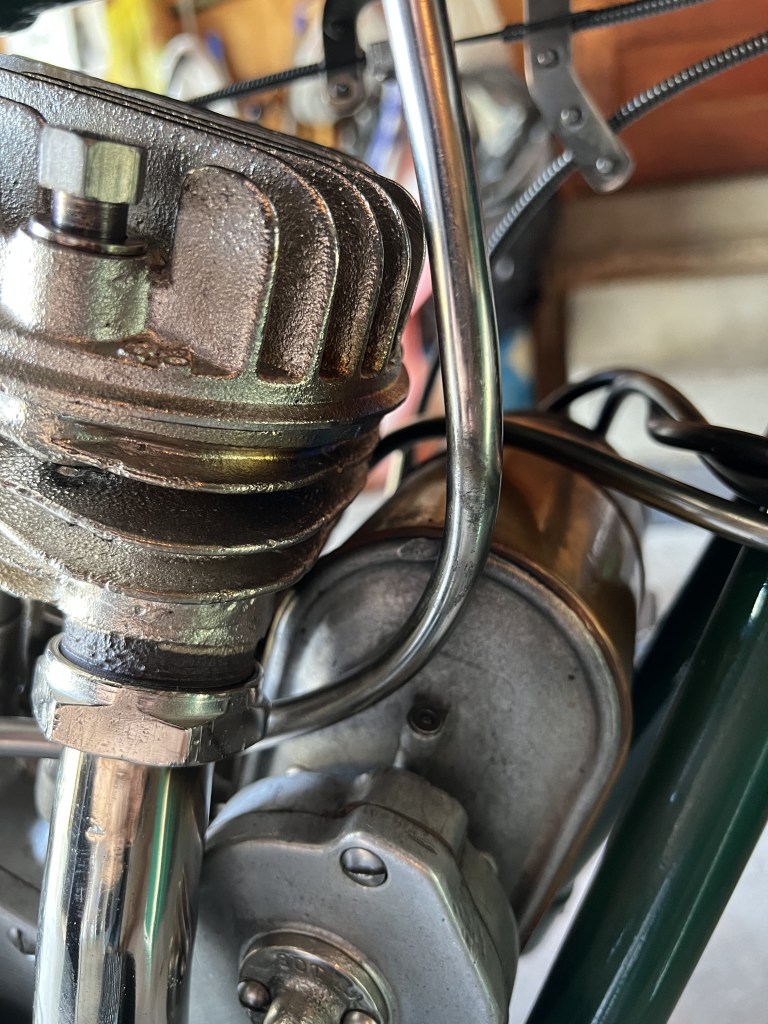

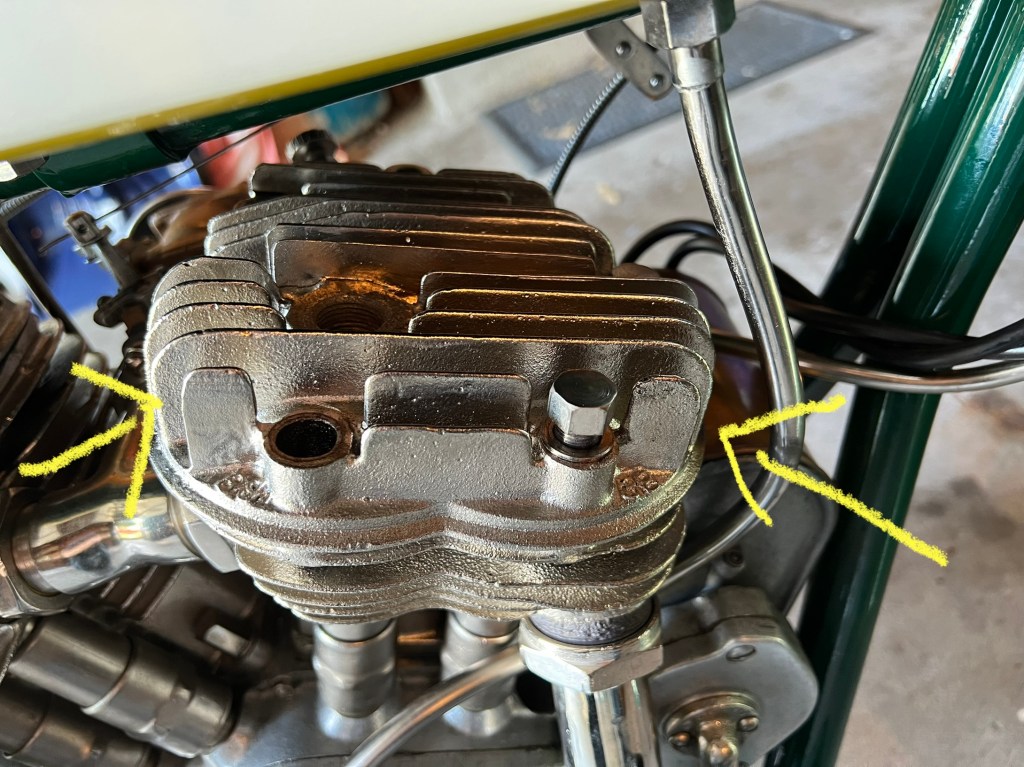

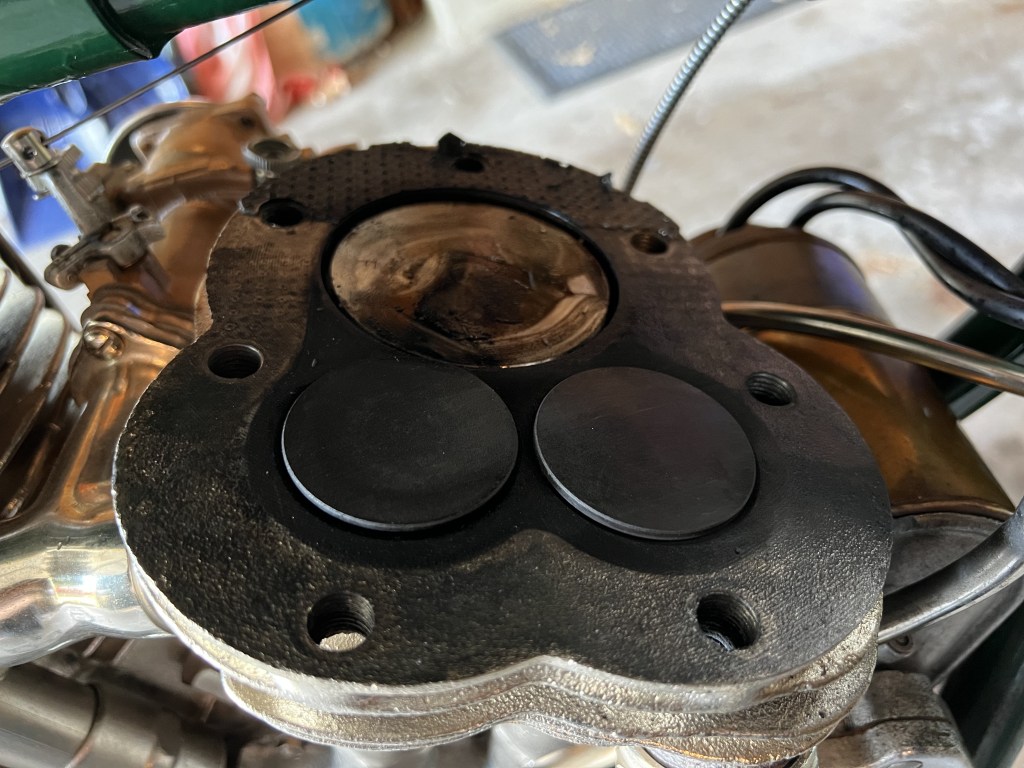

You can see a little scorched area on the nickel oil line in the first picture. It took some heat and a little persuasion to get this last head bolt out. Once out you can see exactly where it burned through the gasket. It is my thoughts that the freshly nickel plated head bolts were the problem. I chased out the threads in the cylinder with a tap. They were fine. I then ran a die down each head bolt. The amount of metal that was removed was surprising. This was all nickel plating. Unfortunately I did not snap a picture of that. Everything threaded nice a smooth so I cleaned off all of the old gasket misted the new gasket with some permatex and snugged down the head. Ran through the heat cycles and snug down procedure and everything is right and tight.

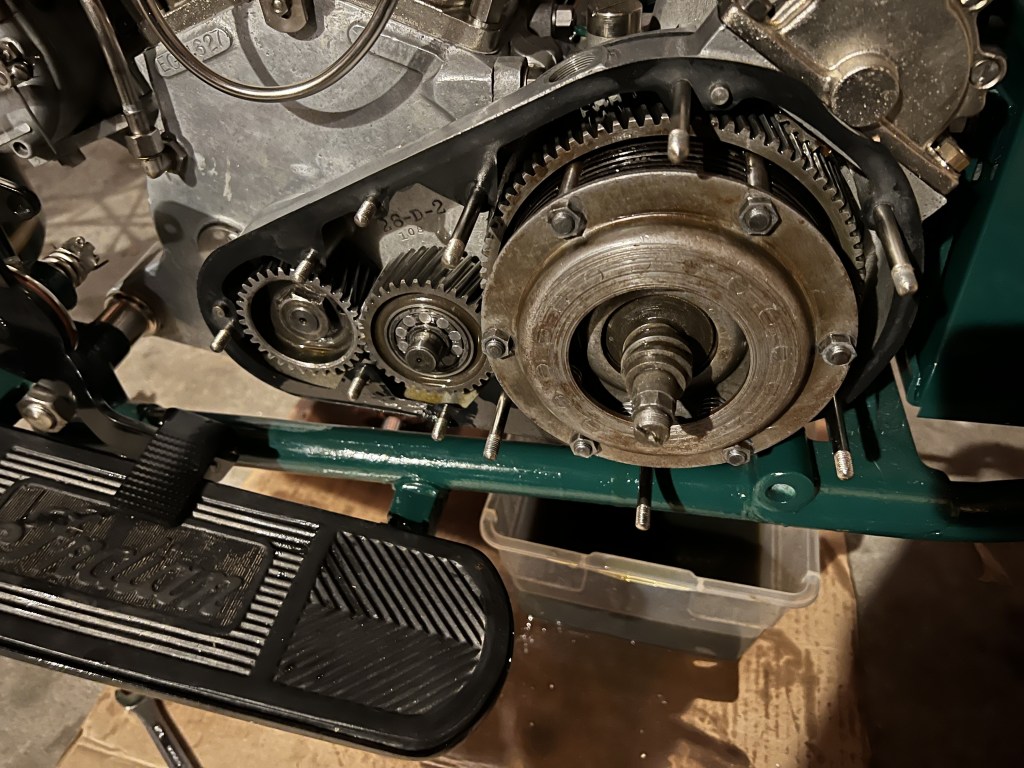

Not nearly as critical but I was not happy with how the clutch was feeling (new plates) and I also had an oil leak where the worm shaft comes out to the clutch engagement arm. This is a common area of oil leaking but also very easy to fix with a little yamabond. So I did dig back into the primary. The 101 scout has a gear drive primary instead of the more standard chan primary. This is one of the reasons this motor is so strong and where the saying “You can’t wear out and Indian scout” comes from. I tried the clutch with a few less springs but in the end I went back to a full set. The new plates just needed to break in a bit. This is not a hobby for anyone who is averse to grabbing a wrench and getting dirty.

I have found that if you notice the precice position the small lever on the clutch housing is when you feel the pull, when the bike wants away, that position must be when the lever is straight up and down, at “12 o clock” or close to that. It sometimes means that the lever must be re-positioned, sometimes turned to the most far back as possible in order to leave ample free play when the clutch is not engaged. Factory instruction advice the lever to be at roughly ” 2 or two o clock, but that is too much far forward. Try that, it gives a better, more precice feel for the off-and-go grab in the pedal.

LikeLike

-edit- Factory instruction advice the lever to be at roughly ” 1 or two o clock” when the clutch is disengaged, but that places the lever too much far forward at the “grab point”. With the clutch lever too much forward the pedal leverage is made harder, shorter and much more difficult to portion smoothly.

LikeLike

Custom fit a thick O-ring instead of the felt seal for the worm shaft. The O ring should fit fairly snug on the shaft but a bit easier at the outer circumferense. Drag adjusted with the knurled nut. Be very aware!! that riding without the tool box installed at the original place on the rear fender an oil leak at the shaft will in worst case result in a very sudden rear brake failure! The wind at speed, a certain specific speed depending on everything else, will carry oil drops right in between the brake bands! Ask me, I ran through without any means of reducing any speed and almost crashed in a busy road junction.

LikeLike

That does not sound fun! Nope, only rode it for the first few heat cycles before the toolbox and other odds and ends got bolted in place. Never though about oil and the rear brake. That must be crazy dangerous with the earlier than 31 101s with the open brake band. At least the drum brakes provide a little protection. Coming off of riding modern motorcycles for so long the stoping is the biggest adjustment. It does still amaze me how well this bike handles. They got so much right with the geometry of the 101’s.

LikeLike

The key to safety when riding Old Iron is to try your absolute best to Never put yourself in a position where you have to stop fast!

LikeLike

Ah, forgot you have a -31 with the rear brake at the right hand side, then there is fewer risks to get oil on the brake bands as with all the earlier Indian Scouts, but still be careful and not overdo when re-grease the wheel bearings. The sealings at the rear hub is not the best and grease can migrate into the brake drum. The -31 rear hub has many parts and is fairly complicate to assemble properly.

LikeLike